There are six Units in Module 4.

Unit 1 focuses on Introduction to Pipe Installation and Safety, Unit 2; Piping

Services, Unit 3; Electricity on Site, Unit 4; Bracket Fabrication, Unit 5; Ancillary

Piping Equipment and Unit 6; Piping system assembly.

In this unit you will be introduced

to good practice guidelines for installing ancillary piping equipment such as

pumps, heat exchangers and valves and how best to orientate and bracket piping

coming to and from this equipment.

Learning Outcome

By the end of this unit each

apprentice will be able to:

·

Identify and describe the main ancillary piping

system components

·

Identify and select the correct pump for the

three most common pumping applications.

·

Explain why pipe lines are installed at low

level, close to walls and accessible to read instruments wherever possible.

·

Explain why safe access to equipment (e.g. heat

exchangers and pumps) is important during commissioning, maintenance and

servicing.

·

List reasons why valves are used in piping

systems.

·

Outline the importance of bracketing pipe work

around equipment to facilitate safe removal of equipment for maintenance and to

ensure that piping does not strain the equipment.

·

Describe the standard procedure for safe

start-up and commissioning of ancillary piping equipment.

·

Recognise the importance of and the need to

retain and file equipment manuals and material certification.

1.0 Ancillary Piping Components

Ancillary piping components are the additional items installed in a

piping system such as pumps, heat exchangers, valves and instrumentation. Their requirements vary depending on the media

being transported in the piping system.

Module 3 unit 2 has dealt with pumps, valves and basic instrumentation

so this module will examine the different type of common heat exchangers and

evaluate different pumps against specific pump selection criteria.

1.2Types of Heat Exchangers

A heat exchanger is a device built for

efficient heat transfer from one medium to another. The heating or cooling media

is separated from the product to be heated or cooled by a solid wall, so that

they never mix. There are three primary

classifications of heat exchangers according to their flow arrangement. In

parallel-flow heat exchangers, the two fluids enter the exchanger at the same

end, and travel in parallel to one another to the other side. In counter-flow

heat exchangers the fluids enter the exchanger from opposite ends. In a

cross-flow heat exchanger, the fluids travel roughly perpendicular to one

another through the exchanger. The

counter current design is most efficient, in that it can transfer the most heat

from the heat (transfer) medium. For

efficiency, heat exchangers are designed to maximize the surface area of the

wall between the two fluids, while minimizing resistance to fluid flow through

the exchanger. The exchanger's performance can also be affected by the addition

of fins or corrugations in one or both directions, which increase surface area

and may channel fluid flow or induce turbulence. We will deal the 2 most common types of heat

exchangers:

·

Shell and Tube Heat Exchanger

·

Plate Heat Exchanger

1.3 Shell and Tube Heat Exchanger

Shell

and tube heat exchangers consist of a series of tubes (see Figure 1). One set

of these tubes contains the fluid that must be either heated or cooled. The

second fluid runs over the tubes that are being heated or cooled so that it can

either provide the heat or absorb the heat required. A set of tubes is called

the tube bundle and can be made up of several types of tubes: plain,

longitudinally finned, etc. Shell and Tube heat exchangers are typically used

for high pressure applications (with pressures greater than 30 bar and

temperatures greater than 260°C). This

is because the shell and tube heat exchangers are robust due to their shape.

There

are several thermal design features that are to be taken into account when

designing the tubes in the shell and tube heat exchangers. These include:

·

Tube diameter: Using a small tube diameter makes

the heat exchanger both economical and compact. However, it is more likely for

the heat exchanger to foul up faster and the small size makes mechanical

cleaning of the fouling difficult.

·

Tube thickness: The thickness of the wall of the

tubes needs to be considered for the following factors; flow rates, pressure

ratings and corrosion requirements.

·

Tube length: heat exchangers are usually cheaper

when they have a smaller shell diameter and a long tube length which reduce the

labour for manufacture. However this

must be considered in conjunction with space on site to install and the need to

withdraw the tube bundle for servicing.

·

Tube pitch: (i.e., the centre-centre distance of

adjoining tubes) needs to be considered as a large tube pitch leads to a larger

overall shell diameter which leads to a more expensive heat exchanger while a

narrower tube pitch can cause inefficient heat transfer.

·

Tube corrugation: this is mainly used on the

inner tubes to increase flow turbulence and heat transfer giving a better heat

exchanger performance.

·

Baffle Design: baffles are used in shell and

tube heat exchangers to direct the fluid in the shell across the tube bundle.

They run perpendicularly to the shell and hold the bundle, preventing the tubes

from sagging over a long length. They can also prevent the tubes from vibrating. (See Figure 2)

Figure 2 – Tube bundle with baffle plates

1.4 Plate and Frame Heat Exchanger

A plate heat exchanger is composed of

multiple, thin, slightly-separated plates that have very large surface areas

and fluid flow passages in between for heat transfer.

Figure 3 – Plate and frame heat exchanger with media connections on head

plate

Plate heat exchangers can differ in the

types of plates that are used, and in the configurations of those plates. Some

plates may be formed with "chevron" (Figure 4a) or other patterns to

increase flow turbulence and therefore heat transfer, where others may have

machined fins and/or grooves. The gasket

design (Figure 4a) allows the heating or cooling medium to flow through every

second space in the plate stack and the product medium to be heated or cooled

flows through the alternate spaces as can be seen in Figure 4b.

Figure 4a – Chevron plate to improve heat transfer, gasket design to direct flow

Figure 4b - Counter current flow in

alternate fluid spaces

While shell and tube heat exchangers are

more suited to high pressure applications plate and frame heat exchangers have

the following advantages:

·

Reduced installation footprint, weighs less and

delivers higher performance

·

Efficient operation with up to 98% heat recovery

or regeneration reduces energy costs

·

Low liquid hold-up enables faster reaction times

to change in process

·

Fluids flow counter-current to each other

between the parallel passages in each pass

·

Full access to both sides of the heat-transfer

surface for inspection, maintenance, and cleaning

·

Access is readily accomplished within the

installed space of the unit, therefore there is no need to allow for additional

“withdrawal” room.

·

Modular design enables expansion of your heat

exchanger as process requirements grow

1.5 Pump Selection Criteria

Pumps transfer liquids from one point to another

by converting mechanical energy into pressure energy (head). The pressure applied to the liquid forces the

fluid to flow at the required rate and to overcome friction (or head) losses in

piping, valves, fittings, and process equipment. Pumping applications include constant or

variable flow rate requirements, serving single or networked loads, and

consisting of open loops (liquid delivery) or closed loops (recirculation systems). When selecting a pump the following points

should be considered:

The pumping system designer must consider

fluid properties, determine end use requirements, and understand environmental

conditions.

·

Pumping rate or flow rate required by the

system, factors to be considered are the usage profiles of the users and the

storage capacity built into the system.

·

Minimum available net positive suction head

(this requires knowledge of the maximum lift required and all head losses on

the intake side of the pump).

·

The discharge pressure required at the point of

use, on top of this flow characteristics of the liquid, friction losses in the

system and any head heights that the pump must overcome need to be considered.

·

Characteristics of the fluid to be pumped (e.g. viscosity,

temperature, solids content, corrosiveness, etc.).

·

Availability of suitable power to drive the

pump. In some instances in a solvent

laden ATEX area, a pneumatic diaphragm pump is used as there is no electrical

requirement to power the pump.

·

Pump location, (e.g., indoors, outdoors,

submerged, in a corrosive environment)

·

Servicing / maintenance requirements of the pump

and availability of spares. This will

also be affected by the operating conditions of the pump and if it is operating

24/7.

Once these and perhaps other site-specific

factors are known, it is possible to consult manufacturers’ literature and

consider the available pumps. A major portion of this process involves consideration

of trade-offs among the reliability, first cost, and operation and maintenance

cost of various pumps having suitable flow/head/efficiency characteristics. Table 1 below highlights the advantages relative

to each other of the following 3 pumps and why they would be selected for a

particular duty:

·

Centrifugal pumps

·

Diaphragm pumps

·

Drum pumps

Pump Characteristic

|

Centrifugal

|

Diaphragm

|

Drum

|

Flow

Rate

|

High

|

Medium

|

Low

|

NPSH

|

Needs

a positive head

|

Can

suck liquid into pump from below

|

Can

suck liquid into pump from below

|

Pressure

|

Normally

low

|

Medium

|

High

|

Viscosity/

solids content

|

Low

|

High

|

Medium

|

Power

supply

|

Electrical

|

Compressed

Air

|

Electrical

or Compressed air

|

Location

|

Supplier

dependant

|

Supplier

dependant

|

Supplier

dependant

|

Maintenance

|

Low

|

Medium

|

Medium

|

2.0 Piping Installation

2.1 Design of Equipment Layout/Pipe Routing

First the basis of design is established, the equipment and materials of

construction selected and the Process Flow Diagram (PFD) agreed for a process

piping system. The next step is to move

on to a more detailed design of the system.

The P&ID provides a schematic layout of the equipment, valves,

instrumentation and line sizes. It is

however not drawn to scale and only present the relationship or sequence between

components and how they interact to control the systems functions.

The physical layout of the major items of

equipment, valves and instrumentation is vital to the ergonomic operation of

the plant long after the construction phase is complete. The interconnection pipework and bracketing

of same is also critical to facilitate ease of access and future maintenance of

the system. While this list is not exhaustive the

following points should be considered when finalizing equipment and piping

layouts:

·

Adequate space for personnel to access system

monitoring instrumentation and to access equipment to regularly inspect for

signs of leaks or wear.

·

Space for removal of internal components for

maintenance (e.g. tube bundles from heat exchangers or agitators from the top

of a vessel.)

·

Thermal expansion and contraction of short runs

of pipework in a plant room can in many instances be catered for by avoiding routing

pipe in straight lines and introduce bends instead.

·

Pipe routing should utilize the surrounding

structure for support where possible. Horizontal and parallel pipe runs at

different elevations should be spaced for branch connections and also for independent

pipe supports.

·

Sufficient and well designed bracketing should ensure

that no undue stresses or forces are transmitted to system equipment which may

cause premature failure of bearings etc.

Supports are also important to retain pipework and facilitate ease of

removal of equipment for servicing.

·

Consideration should be given to other trades when

installing pipe and should be coordinated to accommodate electrical conduit

requirements, civil requirements for drains and clearances for pipe insulation

where required.

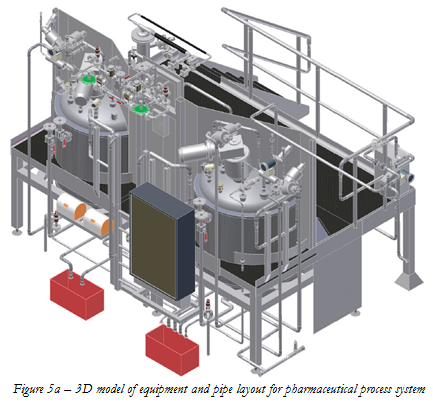

The layout of equipment and pipe routing is greatly

aided by the use of 3D modeling software (see Figure 5a and 5b) which allows

piping designers to visualize the complete installation and zoom in on

congested areas to check for clashes of valves and instrumentation. Extensive component libraries allow the

designer to quickly import standard components to compile the system model

which can then perform static and dynamic stress analyses on pipe and equipment

and indicate the best positions for anchors and supports. Individual isometrics can be exported with

bills of materials for purchasing to procure the necessary materials and the more

sophisticated packages can be linked with ERP systems to provide a complete

costing tool.

2.2 Valve Selection

For liquid piping systems, valves are the

controlling element. Valves are used to isolate equipment and piping systems,

regulate flow, prevent backflow, and regulate and relieve pressure. The most

suitable valve must be carefully selected for the piping system. The minimum design

or selection parameters for the valve most suitable for an application are the

following: size, material of construction, pressure and temperature ratings,

and end connections. In addition, if the valve is to be used for control

purposes, additional parameters must be defined. These parameters include: method of

operation, maximum and minimum flow capacity requirement, pressure drop during

normal flowing conditions, pressure drop at shutoff, and maximum and minimum

inlet pressure at the valve. These parameters are met by selecting body styles,

material of construction, seats, packing, end connections, operators and

supports.

2.3Ergonomics of Piping Design

While construction schedule and costs drive mechanical contractors to

install piping systems quickly it must be remembered that the final system will

be operated for many years in the future.

For this reason it is critical that proper consideration be given to the

ergonomic layout of the equipment and instrumentation so as to ensure that the

operator can comfortably operate the system.

Simple things such as gauges at an ergonomic height, orientated in an

upright position and with readable sized scales can make the monitoring and

recording of information so much easier.

Ease of access to equipment for periodic inspections and checking for

leaks will ensure that the plant is well cared for and well maintained. Space for removing equipment

`2.4 Case Study of a Centrifugal Pump Set Installation

Isolation Valves

Pumps often need repairs. Sometimes

mechanical seal leakages occur. Pump bearings also need replacement. In order

to carry out such repairs pump needs to isolated. It should have no process fluid so that it can

be worked upon. Installing isolation

valves ensures that no liquid flows towards the pump due to gravity from either

upstream or downstream of pump.

Strainer

A strainer is a 'filter' that prevents

undesirable solid particles to flow upstream and clog the equipments. A

strainer contains a mesh that prevents the particles from flowing through it.

Two main types of strainers are: y-type strainers and basket strainers. Y-type

strainers (shown in figure 6) are used for relatively clean fluids while basket

type strainers are used where greater amounts of particles are present. When running a pump for the first time it is

vital that the strainer is checked on a regular basis as it will often clog up

with construction dirt and debris left over from the system fabrication.

Check valve

Check valves are used to prevent backflow in

the system, if a pump was to malfunction the fluid which has been pumped upstream

would try to flow back towards the pump. In order to stop this from happening a

check valve is used.

3.0 Piping Systems Commissioning

3.1 Process Commissioning

Process

commissioning occurs between the time construction is complete and plant

startup commences. During this period

process commissioning personnel are occupied with the task of ensuring the

facilities have been constructed and assembled according to the engineering

design and the equipment manufacturer’s directions. The objective is to ensure that the equipment

has been properly installed and is ready to receive process materials and operate

as originally conceived.

While

this list is not exhaustive the following points should be considered when

preparing for safe start-up and commissioning of ancillary piping equipment:

·

Commissioning plan and procedures must be

prepared that describe in detail how the various tests will be conducted and

evaluated.

·

A commissioning team assembled of experienced

managers, engineers, plant operators and fitters (these may be from the mechanical

contractor who installed the facility) acting as support staff.

·

The process commissioning procedures must also

describe safety precautions that must be taken before, during, and after the

commissioning process.

·

The detailed commissioning plan should

synchronize the turnover of process units from the mechanical contractor to the

commissioning team.

·

Before the commissioning team will accept any

packages the following should be signed off and available :

a.

DQ and basis of design for each of the systems

in the facility

b.

P&ID System walk-downs

c.

Flushing and

pressure test, test packs.

d.

Chemical cleaning and passivation

e.

IQ and OQ documentation

f.

Equipment suppliers documentation and Operation

and maintenance (O&M) manuals

·

Project planning software, should be used to

organize and control the commissioning process, so that resources can be

scheduled and deployed in the most effective way to ensure that all elements

are eventually commissioned and declared operable.

·

It is essential that there is accurate progress

reporting and feed back from the field, as more often than not the

commissioning of the next system is dependant on the first being a success.

Just

as with the actual construction of the process facility, process commissioning

is a complex activity covering all aspects of the newly constructed facilities.

·

Each element of the process unit is examined and

tested.

·

Process control valves must be stroked,

·

Controller tuning coefficients must be checked.

·

Sensors and analyzers must be calibrated

·

Relief valve settings must be checked,

·

Piping and equipment is often hydrostatically

tested or tested with inert gas again to find and eliminate any leaks which may

occur from final assembly or fitting of sensitive instruments which were

removed for the system pressure test.

·

Strainers, filters and tramp metal collectors

must be installed at critical locations in the piping system to prevent damage

to pumps and control valves.

Coordination

between trades is essential and tasks such as the following will need two or

more trades to verify:

·

Insulation must be inspected and steam tracing

tested.

·

Electrical connections must be checked and

electrical equipment tested where and when it can be done safely.

·

Rotating equipment must be checked for alignment

and manually rotated to ensure there are no interferences. Electrical motors

need to be run to ensure the connections are correctly installed and that the

motor rotates in the correct direction.

Should

problems develop during the startup phase, written plans and procedures should

be in place to empty each process unit in a safe and environmentally compliant

manner so that whatever problems occurred can be fixed. Any defects found during he commissioning

process must be corrected by the contractor before the process unit commissioning

can be declared as complete.

A

major part of process commissioning is in preparing the operating instructions for

the startup of the process. The procedures for a newly constructed plant often

differ from the procedures that would be placed in service after a successful

production campaign. In the case of a newly constructed plant, the procedure

may call for each upstream unit to be brought up to operating temperatures and

pressure and held for a period of time to validate the integrity of the unit

before process material is allowed to flow to the next downstream unit.

3.2 Piping systems Documentation and Validation

More

and more industries have placed an increasing emphasis on quality standards and

documentation in order to expedite their approval process for either their own

internal corporate quality requirements or for external bodies such as the IMB

(Irish Medicines Board) or the FDA (United States Food and Drug Administration). The approval process requires that the

facility in which a new product or drug is produced must be designed,

constructed and commissioned so that it meets the criteria for process

validation.

Validation

is the action of proving, in accordance with the principles of GMP (Good

Manufacturing Practice), that any procedure, process, equipment, material

activity or system consistently leads to the expected results. Documented

evidence provides a high degree of assurance that a specific system, equipment

or process will consistently produce a product meeting its pre-determined

specifications and quality attributes. To put it simply, validation is nothing

more than proving that a process actually works.

Failure

to achieve validation on the first attempt can be very costly to the facility

owner, so maintaining quality from the design phase throughout the construction

process is essential. To this end the

pipe fitter / welder can play a major part in ensuring the following documents

are maintained and collated in a controlled fashion:

·

Collecting and filing material certification for

goods received on site

·

Collecting and filing equipment documentation

and manuals for equipment received on site

·

Use the correct tacking and weld procedures and

ensure that all personnel welder qualifications are kept current.

·

Accurate maintenance of weld record sheets and

isometrics during the fabrication and installation phase.

·

Co-ordinate with inspection companies to ensure

weld inspection is maintained at or above the required % level or that all welds

are examined where 100% traceability is required.

·

Ensure

test packs are completed in the required format and signed off and witnessed by

the relevant personnel

·

Ensure any re-routings or changes in drawings

are recorded properly and that the information is relayed through the proper

channels to ensure accurate “As-built” drawings are handed over to the client.

Exercises

·

Identify 2 advantages and 2 disadvantages of a

plate and frame heat exchanger

·

Identify 2 reasons as to why a centrifugal pump

would be chosen before an air operated diaphragm pump

·

List 3 reasons why good equipment and piping

layout planning is vital for the operation of a facility after handover.

·

Dismantle and examine a pipe strainer and explain

how it protects equipment upstream.

·

Identify 3 ways how a pipe fitter can contribute to

the documentation process for system validation.